Safety features for all ViscoMAX™ multi-shaft mixers include:

- Tank holder with locator pin – tank will always be centered in place

- Lift height limit switch – will not run if unit is raised

- Drive guard – covers belts and pulley

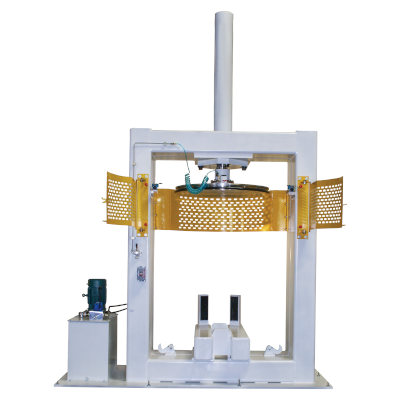

MorehouseCowles ViscoMAX™ multi-shaft mixers are designed for dissolving extremely high viscosity materials of up to 4,000,000 cP. These mixers feature two to three shafts with each having its own specific function to ensure complete homogeneity. Dual or triple motor designs are power matched to your process requirements so you are assured of adequate power availability and efficiency.

Safety features for all ViscoMAX™ multi-shaft mixers include:

For formulation development or small scale production batches, MorehouseCowles offers scaled down versions of our standard dissolvers and mixers ideal for a laboratory setting.

These advanced systems are highly customizable to fit your specific needs. Our technical experts are here to help determine the best configuration to provide you with the best mixing power. From shaft speed or horse power, to tanks, impellers and sweep blade designs, we can help match the technology to your product mix.

Your heavy, viscous products can be effortlessly removed from the tank when you activate the MorehouseCowles hydraulic Ram Discharge System. With a powerful push, your product is forced out of the dispersion tank so it takes less labor and time to empty and clean your equipment.

For optimal performance, it is important to keep up with the preventative maintenance schedule. Recommended parts for the ViscoMAX™ mixers include:

For pricing on MorehouseCowles equipment, complete our request for quote form today.